The Importance of Quality Control in lash wholesale mink Production

As a lash wholesale mink producer, you understand that the quality of your products is everything. In today’s competitive market, consumers demand high-quality lashes that are comfortable to wear and long-lasting. This means that quality control is vital to your success. Without it, you risk losing customers, damaging your reputation, and ultimately going out of business. In this article, we’ll explore why quality control is so important in lash wholesale mink production.

What is Quality Control in Lash Wholesale Mink Production?

Quality control is the process of ensuring that your products meet certain standards of quality. It involves monitoring every stage of the production process, from sourcing materials to packaging and shipping. The goal of lash wholesale mink quality control is to identify any defects or flaws in your products before they reach the customer.

- The Benefits of Quality Control: Implementing a quality control system in your lash wholesale mink production has several benefits: Improved customer satisfaction, reduced product returns and complaints, increased efficiency and productivity and enhanced brand reputation.

- Quality Control Process: The lash wholesale mink quality control process involves several steps: Establishing quality standards; Training employees on quality control procedures; Inspecting raw materials and finished products; Identifying and addressing any defects or flaws; Documenting quality control activities. Implementing a quality control system can help you catch defects early on, saving you time and money in the long run.

- Quality Control Techniques: There are several techniques that can be used in lash wholesale mink quality control: Statistical process control, sampling inspections, root cause analysis, failure mode and effects analysis.

What is Quality Control in Lash Wholesale Mink Production?

By using statistical process control, you can monitor your lash wholesale mink production process and identify any trends or patterns that may indicate a problem.

Benefits of Quality Control in Lash Wholesale Mink Production

Quality control is an essential part of any successful lash wholesale mink production. By implementing a quality control system, you can ensure that your products meet the highest standards of quality and consistency. This can lead to a range of benefits for your business, including:

- Improved Customer Satisfaction: When your lash wholesale mink products are consistently high-quality, your customers will be more satisfied with their purchases and more likely to become repeat customers. This can help you build a loyal customer base and increase your revenue over time.

- Better Reputation: A strong reputation for quality can help you stand out in a crowded market and attract new customers through word-of-mouth recommendations. By consistently delivering high-quality products, you can establish your brand as a trusted and reliable source for lash wholesale mink. You can also achieve this if you buy wholesale eyelash case.

- Reduced Costs: By catching defects early in the production process, you can avoid costly rework or recalls down the line. This can help you save money on materials, labor, and other expenses, and improve your bottom line over time. Implementing a lash wholesale mink quality control system can help you catch defects early and avoid costly mistakes.

- Increased Efficiency: A well-designed lash wholesale mink quality control system can help you streamline your production process and reduce waste. By identifying areas for improvement and implementing changes, you can optimize your workflow and increase your productivity over time.

Benefits of Quality Control in Lash Wholesale Mink Production

Lash wholesale mink quality control can help you identify areas for improvement and increase your efficiency over time.

The Consequences of Poor Lash Wholesale Mink Quality Control

Implementing a lash wholesale mink quality control system is crucial for any business that wants to maintain a positive reputation and keep customers coming back. However, failing to implement a quality control system can have serious consequences for your business.

- Risks Associated with Poor Quality Control: Here are just a few of the risks associated with poor lash wholesale mink quality control: Lost sales – If your products are consistently defective or low-quality, customers will quickly lose faith in your brand and turn to your competitors instead. Damaged reputation – Negative reviews and word-of-mouth can spread quickly online, damaging your reputation and making it difficult to attract new customers. Increased costs – Reworking or recalling defective products is expensive, and failing to catch defects early on can lead to costly mistakes down the line. Reduced efficiency – Without a clear system in place for identifying and addressing quality issues, your production process may become less efficient over time.

- Lost Sales: When your lash wholesale mink products are consistently defective or low-quality, customers will quickly lose faith in your brand and turn to your competitors instead. This can result in lost sales and a decrease in revenue for your business.

- Damaged Reputation: Negative reviews and word-of-mouth about your lash wholesale mink production can spread quickly online, damaging your reputation and making it difficult to attract new customers. This can have long-term consequences for your business, as it may take time and effort to rebuild your reputation. A damaged reputation can take years to repair, and may result in lost business opportunities and decreased revenue.

- Increased Costs: Reworking or recalling defective lash wholesale mink products is expensive, and failing to catch defects early on can lead to costly mistakes down the line. This can result in increased costs for your business and a decrease in profitability.

The Consequences of Poor Lash Wholesale Mink Quality Control

The cost of reworking or recalling defective lash wholesale mink products can be significant, and may include expenses such as shipping, labor, and materials.

The Role of Quality Control in Lash Wholesale Mink Production

In the world of lash wholesale mink production, quality control is essential to ensuring that your products meet the highest standards of quality and consistency. By implementing a comprehensive quality control system, you can identify and address any potential issues before they become larger problems.

Sourcing Materials and Manufacturing Process of Lash Wholesale Mink Products

The first step in any quality control system is to ensure that you’re sourcing high-quality materials.

- Sourcing High-quality Materials: For lash wholesale mink production, this means using only the finest mink fur available. You should also work closely with your suppliers to ensure that they’re meeting your standards for quality and consistency. When sourcing materials, it’s important to consider factors such as the quality of the fur, the consistency of the color and texture, and the ethical and sustainable practices of your suppliers.

- Manufacturing Process: Once you’ve sourced your lash wholesale mink materials, it’s important to monitor every stage of the manufacturing process. This includes everything from cutting and shaping the lashes to applying adhesive and packaging the final product. During the manufacturing process, it’s important to maintain strict quality control standards when working with Vietnam Vin lash merchants. This can include using standardized procedures for each step of the process, training employees on quality control procedures, and regularly inspecting equipment and machinery for defects.

By inspecting each step of the process, you can identify any potential defects before they become larger problems.

Testing and Packaging for Shipping Lash Wholesale Mink Products

Before your lash wholesale mink products leave the factory, they should undergo rigorous testing and inspection.

- Testing and Inspection: This can include visual inspections, weight checks, and even wear-testing by employees or trusted testers. By catching any defects early on, you can avoid costly returns or recalls down the line. During testing and inspection, it’s important to use standardized procedures and checklists to ensure that each product meets your quality control standards. You should also keep detailed records of any defects or issues that are identified during the testing process.

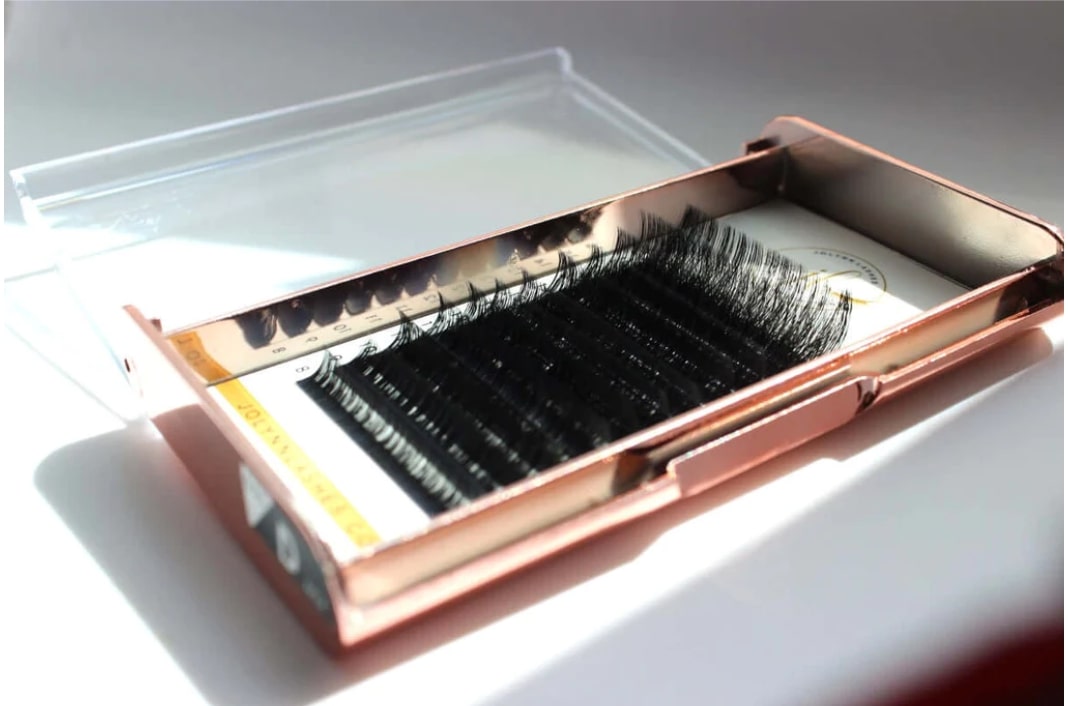

- Packaging and Shipping: Finally, it’s important to ensure that your lash wholesale mink products are properly packaged and shipped. This means using high-quality materials for packaging and taking steps to protect your lashes during transit. You should also work with trusted shipping partners who understand the importance of handling delicate lash products with care. When packaging your products, it’s important to consider factors such as the size and weight of the lashes, the fragility of the lash band, and the potential for damage during transit.

Testing and Packaging for Shipping Lash Wholesale Mink Products

By using high-quality lash wholesale mink packaging materials and taking steps to protect your lashes, you can ensure that they arrive at their destination in perfect condition.

Implementing a Quality Control System in Your Lash Wholesale Mink Business

Now that we’ve covered some of the key elements of quality control in lash wholesale mink production, let’s talk about how you can implement an effective quality control system in your own business.

- Define Your Standards: The first step is to define your standards for quality. Ask yourself these questions: “What do you consider to be a defective lash wholesale mink product? How will you measure quality throughout the manufacturing process?” By establishing clear standards upfront, you’ll have a framework for evaluating your products to buy eyelash glue wholesale supplier at every stage of production.

- Train Your Employees: Quality control is everyone’s responsibility, from the factory floor to the shipping department. Make sure that all of your employees understand the importance of lash wholesale mink quality and know what to look for when inspecting products. Consider offering training sessions or workshops to help reinforce these concepts.

- Use Technology to Your Advantage: There are many tools available today that can help streamline your lash wholesale mink quality control process. For example, you might use automated inspection machines to catch defects more quickly, or invest in software that tracks quality data over time. Look for ways to leverage technology to improve your processes and reduce errors. By using technology to your advantage, you can catch defects more quickly and reduce errors.

- Conduct Regular Audits: Even with the best quality control systems for lash wholesale mink in place, there’s always room for improvement. Conduct regular audits of your processes and procedures to identify areas where you can make changes. Solicit feedback from your employees and customers to gain a better understanding of where you can improve. Regular audits can help you identify areas where you can make changes and improve your quality control system.

- Continuously Improve: Finally, remember that quality control of lash wholesale mink is an ongoing process. Don’t become complacent or assume that your systems are perfect. Instead, strive for continuous improvement by regularly evaluating your processes and making changes as needed.

Implementing a Quality Control System in Your Lash Wholesale Mink Business

Keep in mind that continuous improvement in lash wholesale mink production is key to maintaining an effective quality control system.

Conclusion

Quality control is essential to the success of any lash wholesale mink production business. By implementing a strong quality control system, you can ensure that your products meet the highest standards of quality and consistency. This will not only help you attract and retain more customers but also reduce costs and increase efficiency over time. So take the time to evaluate your current quality control processes and make changes as needed – your bottom line will thank you!